A Monofilament Extrusion Plant is a high-performance system engineered to manufacture PP (Polypropylene), PE (Polyethylene), and PET (Polyester) monofilament yarns. These monofilament lines are used in a wide range of applications—fishing nets, ropes, artificial grass, brushes, filtration fabrics, and industrial textiles.

At TPPL, we design monofilament extrusion machines that deliver consistent filament thickness, exceptional durability, and high-speed production—perfect for demanding industrial needs.

Monofilament Manufacturing Process

Cutting-Edge Monofilament Technology

Advanced extrusion systems for superior yarn consistency

End-to-End Machinery Solutions

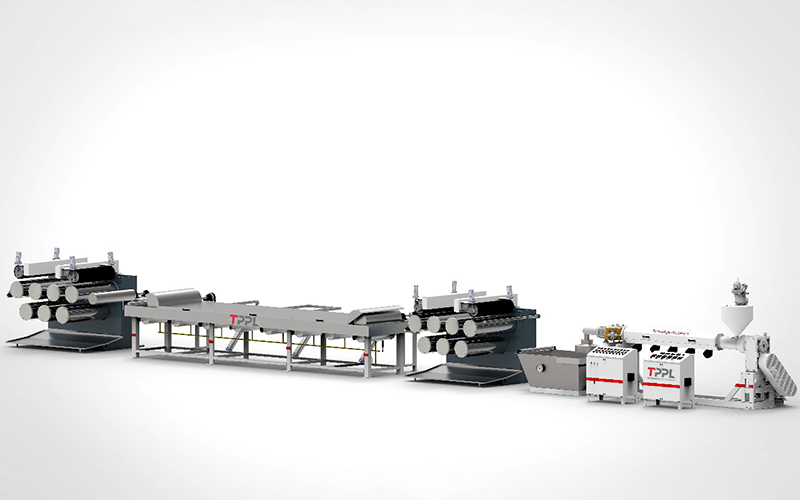

Extrusion → Cooling → Stretching → Winding – Fully integrated plants

Optional units for printing, slitting, and post-processing

Tailored for Your Business

Machines adaptable to filament thickness, color, polymer type, and application

Strong After-Sales Support

On-site installation, training, troubleshooting, and maintenance

Energy-Saving, High ROI

Machines engineered for low power consumption and high yield

Our monofilament extrusion lines support continuous production with minimal operator intervention, reducing downtime and increasing yield.

Optimized extrusion process for low material wastage, reduced energy use, and sustainable production.

Stretching and orientation steps enhance tensile strength, elongation, and weather resistance.

Flexible machine settings for filament diameter, color, polymer type, and end-application.

Modern monofilament extrusion plants have evolved from basic manual operations to fully automated, AI-integrated machines that provide precision, reliability, and speed. Innovations in polymer science and extrusion engineering have made it possible to produce ultra-consistent, high-strength filaments at scale.

TPPL helps businesses build efficient, profitable, and eco-friendly leno bag production lines. Let’s create durable, sustainable, and high-performance packaging together.